Intelligent. Agile. Scalable.

- Industrial & Manufacturing

Your Strategic ODM/OEM Partner for Scalable, Custom-Built Laptops

We bridge the gap between mass-production efficiency and deep customization. Leverage our advanced manufacturing infrastructure and supply chain strength to get precisely the laptops your brand needs, without compromising on volume, cost, or quality.

- About Us

"YiSSiY are a professional industrial laptop factory specializing in high-volume OEM/ODM manufacturing. From motherboard design to full branding, we deliver custom solutions for gaming, enterprise, and public sectors."

Our Vision

To lead the future and sustainability of global computing through intelligent and highly efficient custom manufacturing.

Our Mission

- Empower Global Users

- Innovate Through Technology

- Build Trusted Partnerships

- Our Clients

Trusted by Leading Industries.

We take pride in collaborating with world-class companies that trust Axuon for reliable manufacturing and engineering solutions.

- Engineering Excellence in Custom Laptop

Scalable Customization, Seamless Collaboration.

Join 120+ global brands that trust our manufacturing platform to deliver laptops that stand out in crowded markets. From 100 to 50,000 units – same quality, same expertise.

Precision-built solutions across multiple sectors.

Driven by expertise and innovation.

Expanding our global manufacturing reach.

Proven reliability, quality, and consistency.

- The core issues we address

The Manufacturing Partner You've Been Searching For

YiSSiY provides full-scale OEM/ODM custom laptop manufacturing services that integrate innovation, precision, and sustainability to meet every project need,Bridging the gap between mass production and bespoke needs

Worried about quality variations between prototype and mass production? Our 47-point QC process ensures identical excellence from 100 to 50,000 units.

Frustrated by the high cost of meaningful differentiation? Our modular platform approach delivers unique products while minimizing NRE expenses.

Overwhelmed by coordinating multiple suppliers? We provide single-point accountability from design to delivery, including global logistics and compliance.

Missing market opportunities due to slow response? Our resilient supply chain and flexible production cut development time by 40% while ensuring component availability.

Limited by your manufacturer's technical capabilities? Our engineering team enables hardware-level innovation from thermal solutions to custom BIOS development.

Concerned about scaling challenges? Our flexible manufacturing lines support seamless growth while maintaining quality and delivery commitments.

- Why Choose Us

Your Vision, Our Engineering: Precision-Built Laptops at Scale.

As your strategic ODM/OEM partner, we blend advanced manufacturing with deep customization to deliver bulk laptops that perfectly fit your market needs and brand identity.

Industrial. Industrial. Industrial. Industrial. Industrial.

01

Over 15 years of experience in manufacturing and engineering, trusted by global brands.

02

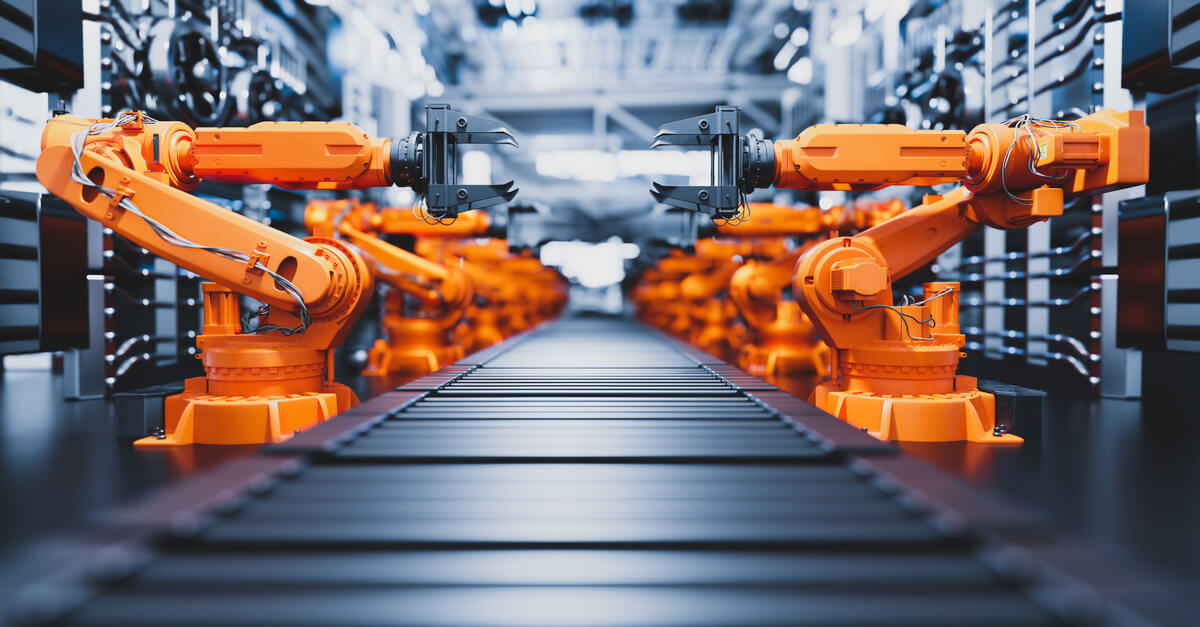

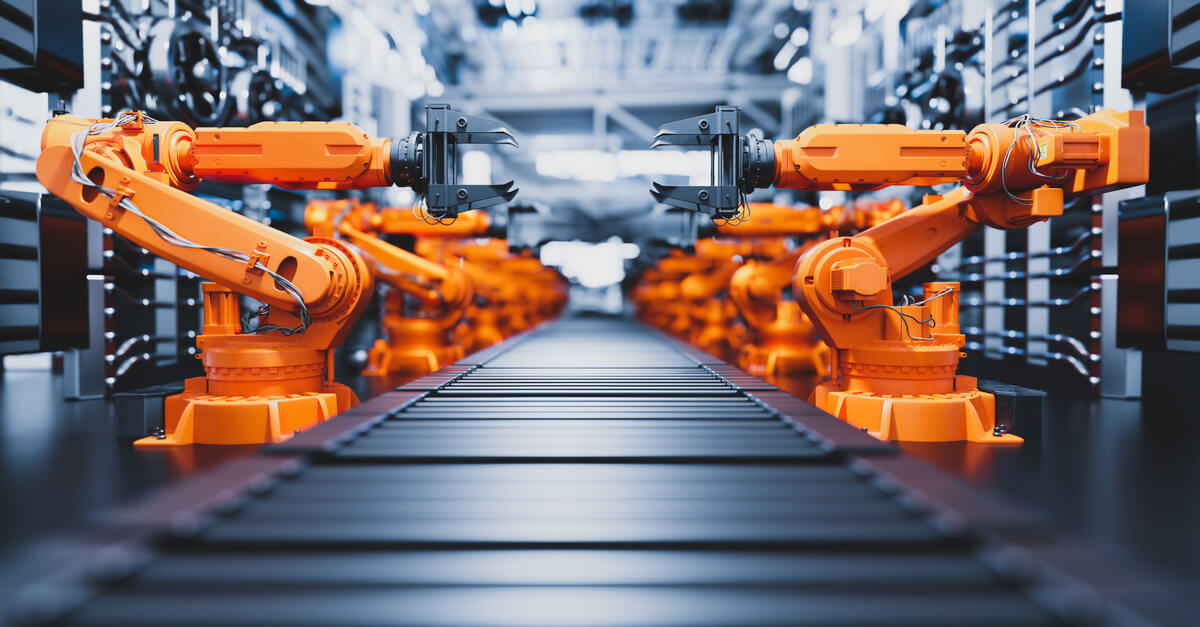

We integrate automation, robotics, and smart systems to enhance efficiency and safety.

03

From design to installation, every project is managed in-house for total quality control.

04

Every component is crafted with meticulous attention to detail and strict quality standards.

05

We offer seamless capacity expansion, allowing you to transition effortlessly from small pilot runs to large-volume mass production to meet fluctuating global demand.

- 15-minute production line changeover time, supporting mixed-model production with multiple configurations

- 4-6 week rapid prototyping cycle

- Seamless production scaling from 100 to 50,000 units

- Real-time production tracking and transparent communication

In fast-changing markets, speed is your competitive edge. Our agile manufacturing ensures you can:

- Seize market opportunities ahead of competitors

- Rapidly test new product concepts

- Adjust product strategies based on user feedback

- Maintain optimized inventory and reduce capital tied up

- Our Process

How We Work.

Every project follows a structured and transparent process

– ensuring quality, safety, and success at every step.

– Your Custom Project, Simplified.

- 1-2 Weeks

Discovery & Analysis

1.Technical requirements review 2.Feasibility assessment 3.Preliminary costing

- 2-4 Weeks

Solution Development

1.Custom engineering design

2.Prototype planning

3.Supply chain preparation

- 4-6 Weeks

Prototyping & Validation

1.Engineering sample produce 2.Comprehensive testing 3.Design refinement

- 8-12 Weeks

Mass Production

1.Production Ramp Plan 2.Quality assurance 3.Continuous delivery

- Our Platform

Delivering Precision, Power, and Performance.

Explore our latest engineering and manufacturing platforms that showcase our expertise in creating high-performance, future-ready custom laptop solutions.

Expanding SteelForge Plant for Higher Output

Boosted overall production capacity by 40% through advanced automation and structural expansion.

SteelForge

Upgrading Nova Energy with Smart Automation

Integrated AI-based control systems to reduce downtime and increase energy efficiency.

Nova Energy

Expanding SteelForge Plant for Higher Output

Boosted overall production capacity by 40% through advanced automation and structural expansion.

SteelForge

Upgrading Nova Energy with Smart Automation

Integrated AI-based control systems to reduce downtime and increase energy efficiency.

Nova Energy

“Every platform we build reflects innovation, precision, and long-term reliability.”

- Real Stories

Trusted Feedback from Industrial Partners.

Our clients’ satisfaction defines our success. Here’s what they say about working with YISSIY.

Operations Director, SteelForge

“Yissiy’s engineering precision transformed our plant efficiency. Their team delivered beyond expectation — on time, on budget, and with outstanding professionalism.”

Head of Automation, Nova Energy

“We’ve never seen such smooth integration of smart systems. Axuon’s expertise in industrial automation truly elevated our operations.”

CEO, ThermoTech Manufacturing

“Yissiy proved to be a reliable partner for our long-term expansion plan. Their technical insight and precision made all the difference.”

Senior Engineer, Mecatronix Group

“Their project management process is exceptionally organized. Communication was clear, and results were even better than projected.”

Production Supervisor, Constructa

“Yissiy’s team worked seamlessly with ours to deliver a high-capacity manufacturing system. Truly dependable and detail-oriented.”

Operations Manager, Enervolt

“Yissiy’s innovative approach helped us modernize production lines quickly. Their commitment to precision is second to none.”

- Frequently Asked Questions About Laptop oem/odm.

Have Questions?

Find answers to the most common questions about our custom built laptop manufacturing services and processes.

Still have questions?

What is the typical MOQ for a custom laptop project?

Our standard Minimum Order Quantity starts at 500 units for most customizations. However, we offer flexible MOQ options for projects involving novel designs or strategic partnerships.

What is the difference between ODM and OEM laptop manufacturing?

OEM involves customizing our existing laptop models with your brand and specifications. ODM entails a completely new design from the ground up, tailored to your unique vision. We provide comprehensive services for both models.

How long does it take from concept to mass production?

A typical ODM project takes 4-6 months, including design, prototyping, and testing. An OEM project based on an existing model can be completed in 8-12 weeks.

What level of hardware customization do you offer?

We offer deep hardware-level customization, including motherboard (PCB) design and layout, custom thermal solutions (fans, heat pipes, vapor chambers), chassis/material selection, and I/O port configuration. This goes far beyond simple component selection.

Can you handle software, firmware, and branding integration?

Absolutely. We provide complete software imaging, custom BIOS/UEFI development, branded boot logos and user interfaces, driver optimization, and fully branded packaging—ensuring the product is uniquely yours from the first boot.

How do you ensure quality control for custom and bulk orders?

Every unit undergoes a rigorous 47-point quality control process, including 72-hour burn-in testing, performance benchmarking, and reliability tests based on MIL-STD-810H standards. Our line first-pass yield exceeds 98%.

What certifications can you manage for global markets?

We manage the full certification process for all major markets: CE/FCC/RED for Europe/USA, CCC for China, KC for Korea, BIS for India, and others like UL, RoHS, and REACH. We ensure your products are market-ready.

How scalable and stable is your supply chain?

We maintain a resilient, multi-sourced supply chain for critical components and hold strategic buffer inventory. This allows us to support production scaling from hundreds to tens of thousands of units per month reliably.

Who owns the intellectual property (IP) for a custom ODM design?

For ODM projects, you retain full ownership of the product design and intellectual property developed specifically for your brand. We act as your manufacturing partner, with clear IP agreements in place.

What does your post-production support include?

We provide comprehensive support including warranty fulfillment, repair services, spare parts management, and even future product refresh planning. We are your long-term partner for the entire product lifecycle.

- Get Started

Ready to Build Your Perfect Laptop Line?

Let’s discuss your project requirements. Our engineering and sales team is here to provide a solution that scales with your success.